WHERE IDEAS BECOME REALITY

D-Terra Solutions, celebrated the grand opening of our new 5,000 square foot Innovation Center in Powell, Ohio in 2017.

The Center was designed to be a collaborative hub for product design and engineering and includes 3D printing, rapid prototyping, investment casting and testing capabilities.

The collaborative space showcases the history of the Company as well as the many of the products that have been designed, developed and manufactured for customers in the automotive, consumer, medical and industrial markets.

The facility represents D-Terra’s world class ‘design through delivery’ expertise as well as our focus on helping clients’ achieve commercial success.

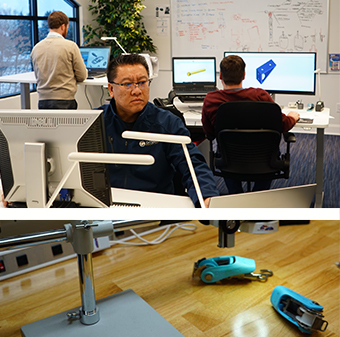

Engineering

The Center has an engineering space that provides a collaborative working atmosphere for our clients and team.

Engineering modeling is conducted collaboratively with our clients to provide 3D architecture of parts and assemblies during the development process. These can be used to 3D print component parts in an iterative design process.

Our engineers utilize Lean/Six Sigma tools such as Design of Experiments (DOE), Failure Modes and Effects Analysis (FMEA) amongst other analytical techniques.

D-Terra is ISO 9001: 2015 certified and is working towards IATF 16949 and ISO 14001 certification. Most of D-Terra’s supply partners are ISO 9001: 2015, IATF 16949 and ISO 14001 compliant.

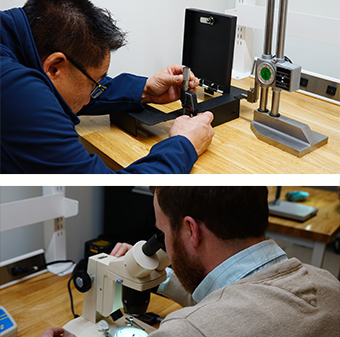

Laboratory and Testing Facilities

The Innovation Center contains an engineering lab equipped with microscopes, measuring and testing equipment for development and inspection purposes.

Where more extensive testing is required D-Terra works collaboratively with globally recognized laboratories to achieve certifications including:

- UL

- CE

- FCC

- FDA

- CPSC

- DOT

- ISTA (Packaging)

- ASTM

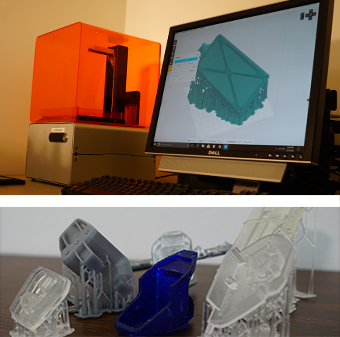

3D Printing and Prototyping

D-Terra has Stereolithography (SLA) 3D printers to create component parts to evaluate usability, fit, and function during the development process.

D-Terra has prototyping capabilities that include:

- Investment Casting

- Plastic Injection Molding

- Machined and Fabricated Metal Parts

- Vacuum Forming