NEWS

Strategic Sourcing Diversification – The Imperative for Resilient Supply Chains in 2025

[Powell, OH] – In an era defined by persistent volatility – from geopolitical tensions and climate disruptions to shifting trade policies – the fragility of concentrated production sourcing has been laid bare. Companies clinging to single-region or limited-supplier models face unprecedented operational and financial risks. At D-Terra Solutions, a leader in integrated manufacturing solutions, strategic consulting, and global supply chain services, we assert that proactive diversification of production sourcing is no longer optional; it’s the cornerstone of resilient, competitive business.

The High Cost of Concentration:

Recent years have served as a stark reminder: over-reliance on any single geography or supplier is a significant vulnerability. Disruptions, whether logistical bottlenecks, political instability, or unexpected regulatory shifts, can cripple production, erode margins, and damage customer relationships overnight. The “just-in-time” efficiency model, while valuable, often lacks the buffer necessary for today’s unpredictable landscape.

Beyond “China+1”: Building a Holistic Diversification Strategy:

While the “China+1” narrative gained traction, true resilience demands a more nuanced, multi-faceted approach. D-Terra guides clients beyond simple geography shifts towards a comprehensive sourcing ecosystem:

- Strategic Regionalization: Evaluating optimal manufacturing footprints combining nearshoring (closer to end-markets for speed and flexibility), friendshoring (aligning with politically stable partners), and selective offshoring (for specific cost or capability advantages).

- Robust Multi-Sourcing: Developing qualified secondary and tertiary suppliers for critical components, often spread across different regions. This mitigates the risk of a single point of failure.

- Supplier Portfolio Optimization: Rigorously assessing supplier capabilities, financial health, risk profiles (including ESG factors), and redundancy. It’s about quality and reliability, not just quantity.

- Technology-Enabled Agility: Leveraging supply chain visibility platforms, predictive analytics, and digital twins to monitor risks in real-time, simulate disruptions, and pivot sourcing strategies dynamically.

- Enhanced Buffer Strategies: Intelligently recalibrating inventory policies and safety stock levels for critical items, balancing cost with risk mitigation.

How D-Terra Empowers Your Diversification Journey:

We don’t just advise; we execute. Our integrated service offering provides the end-to-end support needed to successfully navigate this complex transition:

- Product Development: From initial design to development, we’ll get you there sooner with better results.

- Manufacturing Sourcing & Execution: Identifying, qualifying, and onboarding best-fit manufacturing partners globally. We manage the entire production process, ensuring quality and compliance across your diversified network.

- Strategic Supply Chain Consulting: Conducting in-depth risk assessments, developing tailored diversification roadmaps, optimizing logistics networks, and implementing robust supplier management programs.

- End-to-End Supply Chain Services: Providing seamless logistics, warehousing, inventory management, and customs brokerage to support your geographically dispersed operations.

- Risk Intelligence & Mitigation: Offering advanced analytics and monitoring tools to identify emerging threats and recommend proactive countermeasures.

- ESG Integration: Ensuring your diversified sourcing strategy aligns with sustainability goals and ethical sourcing standards.

The Path Forward:

“Diversification isn’t merely about spreading risk; it’s about building strategic optionality and unlocking new efficiencies,” says Mike Billman, Executive Vice President at D-Terra Solutions. “Companies that proactively invest in a resilient, diversified sourcing network will be the ones best positioned to weather future storms, capitalize on emerging opportunities, and deliver reliably to their customers. Waiting for the next disruption is a strategy for failure.”

D-Terra Solutions is committed to being your trusted partner in building a supply chain that is not only efficient but inherently resilient. We combine deep manufacturing expertise, strategic insight, and global execution capabilities to future-proof your operations.

About D-Terra:

D-Terra Solutions is a leading provider of product development, manufacturing, supply chain, and logistics solutions. With a focus on innovation, efficiency, and customer satisfaction, we empower businesses to optimize their operations, mitigate risks, and achieve sustainable growth through innovative and resilient supply chain strategies. With expertise spanning automotive, building material, and consumer products, we deliver tailored solutions for a complex world.

D-Terra Solutions Partners with CIFT to help revolutionize food production

Powell, OH

From smart utensils to AI powered vision systems, D-Terra’s team of engineers in collaboration with CIFT (The Center for Innovative Food Technology), are helping to power more valuable and efficient food production and manufacturing techniques.

D-Terra Solutions, known for its expertise in manufacturing and precision engineering, is bringing its technological prowess to the food sector with a suite of automated tools designed to enhance efficiency, safety, and scalability in food processing. With a vision to help producers meet rising global demands, D-Terra’s engineers are at the forefront of developing innovative systems that could significantly streamline food production workflows.

Erik Gray, Product Development Engineer, has been the lead on several highly technical automation programs that require software development and embedded firmware that work in harmony with our hardware design to ensure the systems meet customer specifications and performance requirements.

The primary goals of D-Terra’s work have been extensive systems research and development, followed by pilot programs with select food producers. The success of these pilots could see the technology scaled for widespread adoption, offering the food industry a much-needed solution to modern production challenges.

Project examples include:

- Grote/Platter food temperature monitoring system

- Henny Penny vision system

- Pro-Pak Industries proof of principle prototype packaging machine

- Hirzel Canning Company vision system

For food producers and industry stakeholders, the D-Terra-CIFT partnership represents a promising avenue to modernize and strengthen food production systems in a sustainable, tech-forward way.

About D-Terra Solutions

D-Terra Solutions specializes in advanced engineering, manufacturing, and automation solutions across multiple industries. With a team of expert engineers and a commitment to innovation, the company seeks to transform traditional processes with intelligent, automated solutions.

About CIFT

The Center for Innovative Food Technology (CIFT) is a leading nonprofit dedicated to advancing the food industry through innovative practices, research, and partnerships. Based in Ohio, CIFT collaborates with businesses to promote efficient, sustainable, and modern food production methods.

Navigating the Complexities of Geo-Political Supply Chain Factors

In today’s interconnected global economy, businesses operating in the manufacturing, supply chain, and logistics sectors face an array of challenges influenced by geopolitical factors. From trade tensions and regulatory changes to geopolitical conflicts and natural disasters, these external forces can significantly impact the flow of goods and services across borders. As a leading provider with over 30 years of manufacturing, supply chain, and logistics solutions, D-Terra Solutions understands the importance of navigating these complexities effectively to ensure operational resilience and continuity.

Understanding the Impact of Geo-Political Factors

Geo-political factors encompass a wide range of influences, including government policies, international relations, economic sanctions, and geopolitical tensions. Changes in these factors can disrupt supply chains, increase costs, and introduce uncertainty into business operations.

Ongoing wars in Ukraine and the Middle East, for instance, have the potential to disrupt vital trade routes and supply chains well in to 2024 and beyond, affecting the movement of goods and raw materials across regions. According to S&P Global, the Russia-Ukraine conflict continues to pose a greater risk to worldwide trade and commodity markets.

Similarly, growing tensions in the Suez Canal and ongoing conflicts in key shipping lanes have led to shipping delays and increased transportation costs. According to the Financial Times, the threats to shipping vessels have been greatly curtailed, but the risk is not completely eliminated. Despite the reduced hazards, many shipping companies continue to redirect routes through Europe and Asia.

Just-in-Time vs. Just-in-Case Inventory Planning

One of the key considerations for businesses is the balance between just-in-time (JIT) and just-in-case (JIC) inventory planning. While JIT inventory management minimizes carrying costs and improves efficiency, it can leave businesses vulnerable to supply chain disruptions. On the other hand, JIC inventory planning involves holding larger inventories as a buffer against unforeseen events, providing greater resilience but potentially increasing costs. Starting with the COVID-19 pandemic in 2020, many manufacturers moved more towards a JIC approach in response. Three years later, the trend is reversing again due to higher interest rates making it more costly to maintain larger inventories. “Flexibility is increasingly more important when it comes to supply chain logistics. To be able to anticipate changing market needs and pivot strategies accordingly gives companies a leg up when a major disruption occurs.”, said D-Terra’s EVP, Mike Billman.

Alternative Suppliers to China

As geopolitical tensions and trade disputes continue to escalate, businesses are exploring alternative suppliers to China for manufacturing. Countries in Southeast Asia, such as Vietnam, Thailand, and Malaysia, are emerging as attractive options for diversifying supply chains and reducing dependence on China. By diversifying their supplier base, businesses can mitigate risks and ensure a more robust and resilient supply chain. D-Terra Solutions has been working to address this diversification with our customers by providing manufacturing, logistics and warehousing services in India, Turkey, Mexico and Europe. “Although China remains compelling and decoupling can come with significant risks, we act responsibly by providing customers with options from various geographic regions. Ultimately, it’s their decision as to what makes best sense for business” said D-Terra’s EVP, Mike Billman.

Conclusion

As global dynamics continue to evolve, businesses in the manufacturing, supply chain, and logistics sectors must remain agile and adaptable to navigate the complexities of the global marketplace. By understanding the impact of geo-political factors, implementing proactive risk management strategies, embracing digital technologies, and building collaborative partnerships, companies can enhance their resilience and ensure continued success in an ever-changing world.

At D-Terra Solutions, we are committed to helping our clients navigate the challenges of today’s global landscape. With our expertise in manufacturing, supply chain, and logistics, we stand ready to support businesses in optimizing their operations and overcoming obstacles to growth. Contact us today to learn more about how we can help you navigate the complexities of geo-political supply chain factors.

About D-Terra Solutions:

D-Terra Solutions is a leading provider of product development, manufacturing, supply chain, and logistics solutions. With a focus on innovation, efficiency, and customer satisfaction, we help businesses optimize their operations and achieve their strategic objectives. Visit our website here to learn more about our services and how we can support your business.

Navigating Success: A Guide to Post-Launch & Logistics Management in Product Manufacturing

November, 2023 – D-Terra Solutions, Powell, OH

In the stages of product manufacturing, the process doesn’t end with the product launch—it evolves into a critical phase involving post-launch and logistics management. This phase is vital for companies aiming to sustain their success and thrive in a competitive market. In this article, D-Terra Solutions explores the significance of post-launch and logistics management (a process D-Terra holds integral to our clients’ success) and offers insights into best practices.

The Importance of Momentum, Quality, and Optimization:

- Maintaining Momentum: Effective post-launch management involves strategies to keep the momentum of a new product alive through targeted marketing, customer engagement, and continuous improvement based on customer feedback. Think of your selling channels, customer demographics, and determine a customer needs map that will inform future product decisions.

- Quality Assurance: Ensuring product quality is an ongoing commitment. Post-launch management includes monitoring product performance, addressing any issues that may arise, and implementing improvements. A proactive approach to quality assurance builds trust among customers and enhances the brand’s reputation. D-Terra Solutions utilizes ISO and IATF standards to maintain quality throughout the product lifecycle.

- Supply Chain Optimization: A well-optimized supply chain is critical to the success of a product. Collaborating with a reliable supply chain partner ensures a smooth flow of materials, reduces lead times, and minimizes the risk of disruptions. It also allows for better scalability as demand fluctuates.

Risk mitigation is another ongoing process that is critical to a company’s success. After launching a new product, companies must be prepared to navigate various risks, from supply chain disruptions to regulatory changes. Robust logistics management includes risk assessment and mitigation strategies, such as diversifying suppliers or maintaining a safety stock. One does not have to look back too far for an example of how regulatory changes coupled with supply chain disruptions, such as during the Covid Pandemic, have a drastic and negative effect on logistics management.

Additional practices that can be important to consider are sustainability and adaptability:

As sustainability becomes a key focus in the manufacturing industry, integrating eco-friendly logistics practices is crucial. This may involve optimizing transportation routes, reducing packaging waste, and selecting carriers with strong environmental credentials. Certifications from reputable organizations, such as the Forest Stewardship Council (FSC) can help guide companies in sustainable practices.

The market is ever-changing, and post-launch success requires adaptability. A responsive logistics strategy allows companies to adjust to market fluctuations, meet changing customer demands, and capitalize on emerging opportunities.

Collaborating with a Comprehensive Service Provider:

Companies looking to optimize post-launch and logistics management often find value in partnering with comprehensive service providers, like D-Terra Solutions. These partners offer a range of services, including product manufacturing, consulting, and supply chain management. By consolidating these services, companies can streamline their operations, reduce costs, and enhance overall efficiency.

Post-launch and logistics management is a critical point where companies can either solidify their success or fail under the pressures of a dynamic market. Embracing this phase with strategic planning, quality assurance, and an adaptable logistics strategy is key to building a stable and successful brand. By partnering with a comprehensive service provider, companies can navigate the complexities of post-launch and logistics management with confidence, ensuring sustained growth and customer satisfaction.

How to Transform a New Innovation from an Idea to a Successful Product Launch

Every year, 95% of new consumer products launched fail, and many more don’t even make it to market.

For every company that attempts to manage product development internally, there are ten that have learned that the fastest, most efficient way to bring new products to market is by turning to knowledgeable experts. Partnering with D-Terra can help your people and your company stay focused on core strengths and avoid internal stumbling blocks such as staffing changes and shifting priorities.

For over 30 years, D-Terra Solutions has helped hundreds of companies and inventors successfully bring new products to the market.

By managing the design/engineering, manufacturing, transportation and fulfillment aspects of the product commercialization process, D-Terra can streamline product launch activities to eliminate unnecessary delays.

Other advantages to outsourcing product development and manufacturing with D-Terra include:

- Avoid burdening internal staff with job functions outside their core competencies

- Reduce your company’s reliance on overhead- the resources you need are available when they’re most needed

- Gain access to world-class expertise- Tapping into the D-Terra global manufacturing team means each new project is matched with the most appropriate facility

- Engage our Professional Services discipline to help you think “outside-the-box” and find fresh approaches gained from years of combined experience in a variety of industries and product categories.

A History of Success. Our Approach to Product Commercialization

Process discipline is the foundation of the D-Terra business model. The result is the D-Terra Process, an approach to new product development and manufacturing that takes full advantage of proven process engineering and manufacturing techniques to maximize efficiency and improve results. Utilizing Six Sigma and collaborative development philosophies, the D-Terra process is what gives us the ability to deliver products to market on time and on budget, with the highest possible quality.

Phase 1: Project Plan

The Project Plan Phase of the D-Terra process defines business needs, opportunities, and feasibility for the client. Here sales and marketing data is combined with customer critical-to-quality requirements (CTQs) to develop the overall project plan.

Phase 2: Concept Development

In the Concept Development Phase, discovery and definition of product, brand, and communications characteristics important to a successful product, are identified. Specific embodiments are created and evaluated, and one is selected. Product specifications are then developed.

Phase 3: Engineering Development

This phase is comprised of engineering activities required in the development of a manufacturable product. The design is then validated to ensure that the customers’ CTQs are met.

Phase 4: Manufacturing Systems Development

In this phase of the process, Manufacturing Systems Development, the manufacturing, and supply chain infrastructure is put in place. Tools and equipment are debugged, and pre-production samples are built and approved. Market confirmation testing is performed, and the product launch plan is deployed.

Phase 5: Pilot

In the Pilot Phase, significant quantities of the product are manufactured in the production environment and the manufacturing process capability is validated. Final product testing is performed, and customer approval obtained to begin volume production.

Phase 6: Production

In the Production Phase, manufacturing ramp-up occurs to achieve the required capacity and throughput. Product inventory is built, and distribution channels filled in accordance with the product launch requirements.

Phase 7: Post-Launch Management

The seventh phase, Post-Launch Management, involves maintenance and continuous improvement of production and supply chain, logistics activities through Six Sigma methodology. Key focus areas in this phase include identifying potential cost reduction opportunities and Multi-Generation Product Planning (MGPP).

Key to the success of any product commercialization project is the D-Terra interdisciplinary team which includes design, engineering, manufacturing, and logistics experts well versed in the D-Terra process. With experience working for such companies as DRiV (Tenneco), Procter and Gamble, Worthington Industries, Console Vault, LKQ, AZEK (TimberTech) and Newell, the professionals at D-Terra provide a level of differentiation few can match.

A few examples of how we’ve helped our clients succeed in the global marketplace can be found in our CASE STUDIES.

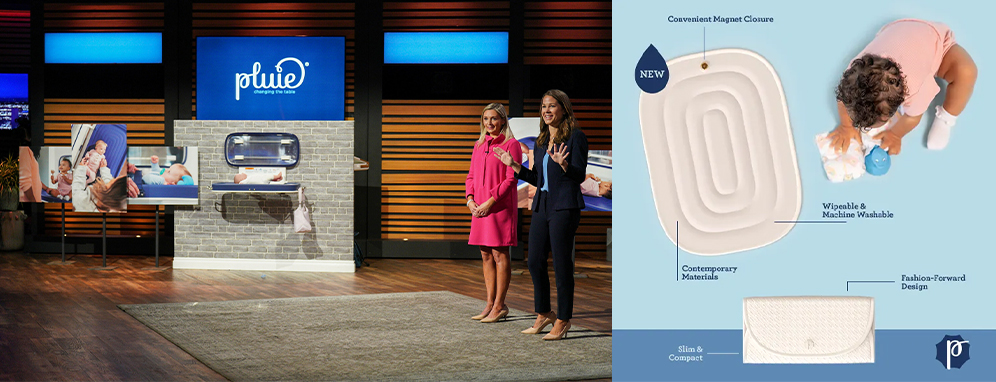

D-Terra Solutions Client Makes a Splash on Shark Tank – Pluie’s Rise to Market

Now backed by D-Terra Solutions manufacturing and engineering expertise, Pluie’s expanding product line aims to deliver on the promise of Changing the Table®.

COLUMBUS, OHIO, UNITED STATES, March 29, 2023 – Pluie approached D-Terra Solutions in September of 2022 to develop and launch a new baby changing mat concept and to help turn a great idea into reality. Prior to their involvement with D-Terra, the Founder and CEO Addie Gundry and Co-founder and COO Brittany Hizer already had an innovative B2B market-ready product, the Pluie P100 Plus With UV-C Light System: A first of its kind self-sanitizing diaper changing table for public restrooms.

On March 10th, the female duo pitched the Pluie P100 Self Sanitizing Changing Table to The Sharks on ABC’s Shark Tank, garnering positive feedback and applause from the Sharks. With their catch phrase, “Together we can change the table”, Gundry and Hizer brought forth a bold pitch forward, but with Business-to-Business products being a rare pitch on Shark Tank, it was not quite yet at the scale and price point to incentive the Sharks.

Currently, Pluie’s revolutionary public changing tables can be found in more than 20 states, including at airports, stadiums, amusement parks, health clinics, retail destinations and more. In Chicago (Gundry’s hometown), Pluie is in Guaranteed Rate Field, Northwestern Pediatric Offices, the Angel Harvey Family Health Center and several CVS locations in Highland Park

D-Terra’s Role:

Pluie is ready to expand their product line to consumers, taking their innovative brand to parents and caregivers everywhere with the Pluie Pret Changing Mat: A compact and machine washable diaper mat for parents on the go. The mat is made out of woven neoprene – one of the only materials that can be both wiped clean and machine washable.

D-Terra is honored to help Pluie deliver on the promise of the consumer. By marrying design and engineering with manufacturability, D-Terra’s time-tested product commercialization process allows Pluie to efficiently navigate the product launch process with a balance of process and speed.. “We were very impressed with the thoroughness of your plan and are confident in your ability to execute… with speed.” Said Melanie Whaley, Pluie’s Director of Brand.

You can read more about the D-Terra Pluie Case Study here.

About Pluie

Established in 2020, Pluie is modernizing the outdated public restroom changing table experience with the world’s first and only self-sanitizing table, powered by a patented UV-C light system. Pluie is committed to Changing the Table® by making sure all parents and caregivers on the go have a clean, safe and comfortable option in every public restroom. Pluie is proudly female-founded, WBENC certified, and operated by CEO Addie Gundry and Co-Founder and COO Brittany Hizer. Pluie is made in the USA, headquartered in Chicago, and was named to Fast Company’s 2021 World Changing Ideas list and TIME Magazine Best Inventions of 2021. For more information, visit hellopluie.com and follow @hello_pluie.

SOURCE: Pluie

D-Terra Solutions Recognized as a Certified Top Supplier for Worthington Industries, Inc.

COLUMBUS, Ohio, October 5, 2022 – D-Terra Solutions has once again earned recognition as a Certified Top Supplier for Worthington Industries, Inc. (NYSE: WOR). Hosted by New Albany Country Club, the event recognized those suppliers who demonstrate world class performance in quality, delivery, cost, and service.

D-Terra’s Executive Vice President Mike Billman, commented, “D-Terra has provided Product Development, Manufacturing Launch, Quality and Supply Chain support services to Worthington Industries for over a decade. We are honored to be recognized as a one of their top suppliers.”

About D-Terra Solutions

D-Terra Solutions is a product commercialization firm with global reach and expertise that spans product design, engineering, manufacturing, and international logistics. From product design to finished goods delivery, D-Terra helps U.S companies compete and win in the global marketplace.

D-Terra provides services and solutions for companies in the Automotive, Consumer and Industrial markets.

About Worthington Industries

Headquartered in Columbus, Ohio, Worthington is a leading industrial manufacturing company. The Company operates 58 facilities in 16 states and nine countries, sells into over 90 countries and employs approximately 9,500 people.

For more information on D-Terra Solutions, Contact:

Mike Billman

Executive Vice President, D-Terra Solutions

- 614.410.3978 | mbillman@dterrasolutions.com

D-Terra Internships – Providing Real World Experience in the Business and Engineering Fields

D-Terra Solutions (D-Terra) has helped provide various internship opportunities for students throughout the years, and this year has been no exception. We have had the privilege of hosting several interns in 2022, including: for the first time ever, two high school interns.

The Metro Early College High School: As the first early college STEM School in Ohio, Metro has helped foster an intellectually vibrant learning community for students. On average, 84% of Metro Students earn college credits before graduation and has provided their students with internships and real world experience within the community.

This year, we hosted 2 Metro High School student internships at D-Terra Solutions. Ismail initiated an in-depth gap analysis project for one of our OE automotive products for the marketing and business development department. Fin assisted our engineering team with functional testing for a new automotive product accessory

Clay Watters: Clay interned for D-Terra over the summer and provided an extended analysis of the business gap project kicked off during the spring Metro Internship projects. With an even deeper dive into the project, the combined efforts of Ismail and Clay allowed D-Terra to identify new opportunities with our OE manufacturing sectors.

Clay is currently attending University of North Carolina at Chapel Hill for his Masters Degree in Global Studies and has an undergraduate degree from Denison University in International Studies with a minor in history.

To receive more information on D-Terra or to hire our team, please contact Mike Billman at mbillman@dterrasolutions.com.

Console Vault, LLC Recognized as Gold Supplier at 2022 Toyota Supplier Conference

D-Terra Solutions is proud to announce that Console Vault is a recipient of the Toyota North America (TMNA) Gold Supplier Award.

D-Terra Solutions has long had a commitment to quality, and when D-Terra and Console Vault teamed up in 2018, that commitment continued through to Console Vault’s product line of In-Vehicle Safes. When Console Vault’s President, Scott Bonvissuto (pictured center right), and D-Terra’s CEO, Denis Bruncak (pictured center left) attended the 2022 Toyota Supplier Conference on April 20th, they had no idea what to expect. It was much to their surprise when Console Vault was announced as a Gold Supplier, an honor reserved for only the top tier percent of suppliers.

In response to receiving the award, Console Vault’s President, Scott Bonvissuto stated “We are extremely pleased and proud to be recognized for this quality award. It is a testament to our ongoing commitment to excellence.” Bruncak adds, “Total customer satisfaction is a pivotal element of D-Terra’s culture and is a team effort executed by the D-Terra and Console Vault Manufacturing, quality, product development and operations teams.

Click Here to read the full Press Release.

Design For Manufacturability: The Advantage of Working with a Full-Service Product Commercialization Firm.

The D-Terra Solutions Advantage:

D-Terra Solutions (D-Terra) has helped bring hundreds of new products to market, but the company sets itself apart as more than just a product design firm. D-Terra takes a holistic phased approach to working with clients, that includes a comprehensive Design through Delivery process that includes:

- Product Design

- Engineering

- Contract Manufacturing (D-Terra as the Manufacturer of Record)

- Manufacturing Consulting

- Quality Control

- Sourcing, Supply Chain and Logistics Services

The Importance of Design for Manufacturability:

When product design takes place in a vacuum, the finished product is not always designed with manufacturability in mind. This can lead to redesign efforts, production launch delays and unnecessary costs. D-Terra’s unique approach includes working closely with the factory as products are designed and incorporating that feedback into the product concept and prototype (s). This process ensures that products are designed right the first time which increases speed to market allowing for better ROI.

With experienced product development, manufacturing and quality teams based in both North America and Asia, D-Terra has helped commercialize over $1.5 Billion in products for US based product companies.

To receive more information on D-Terra or to hire our team, please contact Mike Billman at mbillman@dterrasolutions.com.